When purchasing refractory metals, it is essential to know their weight to ensure that you get precisely what you need. Knowing the weight of your refractory metal requirement (rod, wire, sheet, plate & bar) is important for several reasons.

1. Cost Control – The refractory metals Molybdenum, Tungsten, Tantalum & Niobium are typically priced and sold based on the size & weight of the mill product being purchased. When you know the exact weight of the metal, you can accurately calculate the cost of the material based on its price per unit weight.

2. Efficient Shipping – Refractory metals are dense materials that can be quite heavy. Knowing the weight of the metal beforehand can help you determine the most efficient shipping method to transport the material to your desired location.

3. Process Optimization – Refractory metals often require specialized processing techniques, such as forging or machining, to achieve specific shapes or sizes. Knowing the weight of the material before purchase can help optimize these processes. In addition, the weight of your part may have critical implications to the intended application, as refractory metals have significant densities and are very heavy.

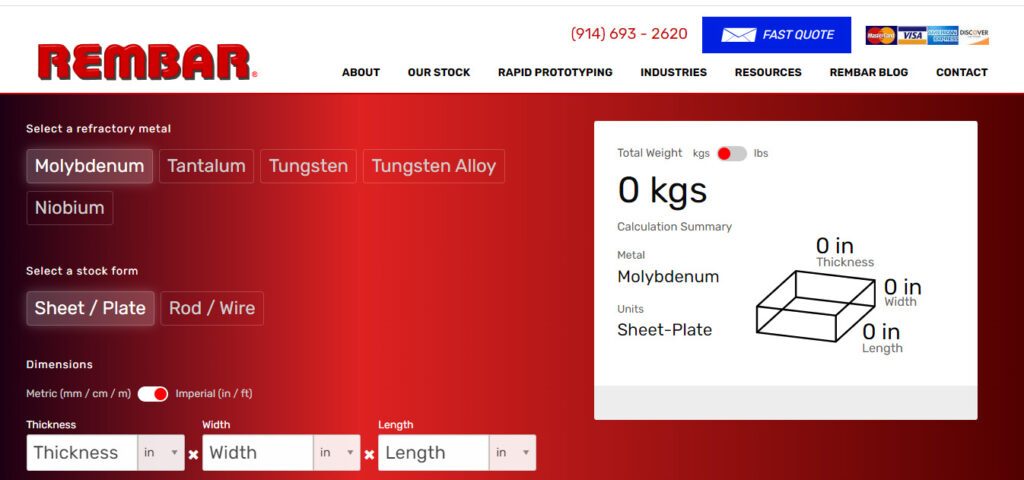

Rembar offers a free & easy refractory metals size-to-weight calculator on our website. Simply select your refractory metal choice (molybdenum, tungsten, tungsten alloys, tantalum or niobium), insert the dimensions of your product and your answer is shown.

https://www.rembar.com/calculator/

For those that are interested in learning the calculations required to determine the weight of a metal object, we offer the following reference guide.

Every metal has a specific density expressed in grams per centimeter3. This is the metal’s mass per unit of volume. Example: Density of pure molybdenum = 10.14 grams/centimeter3. Therefore, in every cubic centimeter of molybdenum, there are 10.14 grams of mass. You can find the specific density of your metal by searching for a “metal density table” on the internet.

The formula used to determine metal weight in kilograms:

Sectional Area (mm2) x Length (m) x Density (g/cm3) / 1,000.

To Calculate the Weight of a Metal Product:

1. Determine the specific density of the metal to be weighed.

If your dimensions are in imperial measurement, convert to metric by dividing the imperial number by .03937 (1 millimeter). Example: 1” x 4” x 6” equals 25.4mm x 101.6mm x 152.4mm

2. Determine the cross-sectional area of your part by multiplying the thickness of the part times the width. Example: Sectional area: 25.4mm thick x 101.6mm wide = 2,580.64mm2

3. Determine the length of your part in meters (1,000 millimeters = 1 meter). Example: Length equals 152.4mm = .1524 meters

4. Multiply the sectional area (mm2) x length (m) x density (grams/cm3) and divide by 1,000 to determine the weight in kilograms. Example: Using the specific density for pure molybdenum plate with measurements of 1” x 4” x 6” (25.4mm x 101.6mm x 152.4mm): 2580.64 x .15240 x 10.14 = 3,987.955 grams / 1,000 = 3.9879 kilograms.

Extensive technical data for molybdenum, tungsten, tantalum & niobium can be found on our website at: https://www.rembar.com/resources-technical-information-on-refractory-metals/technical-data/

Quick Facts;

Pure Molybdenum Information:

Density = 10.14 grams/centimeter3

mgs/200mm = (diameter in mils)2 x 1.0276

Tensile Strength in grams/milligram/200mm = TS in psi/2884

Pure Tungsten Information:

Density = 19.17 grams/centimeter3

mgs/200mm = (diameter in mils)2 x 1.9427

Tensile Strength in grams/milligram/200mm = TS in psi/5453

Pure Tantalum Information:

Density = 16.6 grams/centimeter3

Pure Niobium Information:

Density = 8.57 grams/centimeter3

About Rembar: Over 73 years, Rembar has built a sterling reputation as a trustworthy, reliable supplier of high-quality refractory metal products to industry since our founding in 1950.

From standard mill products (rod, wire, foil, sheet, plate, bar & tubing) to precision-machined & fabricated parts, look to Rembar to satisfy your refractory metal requirement quickly & at competitive prices.