The invention and subsequent commercialization of vacuum furnaces has revolutionized industry and dramatically improved the life & performance of industrial parts & products.

Vacuum furnaces are used in a variety of industries, including metallurgy, aerospace, and the automotive industry. They are used for a wide range of applications, such as sintering, brazing, and thermal treatment of metals, ceramics, and composites.

The primary benefit of using a vacuum furnace is that it allows for materials to be heated without the presence of oxygen, which eliminates the risk of oxidation and other unwanted chemical reactions. Additionally, the absence of oxygen results in an extremely clean atmosphere, which is essential for certain types of advanced fabrication processes.

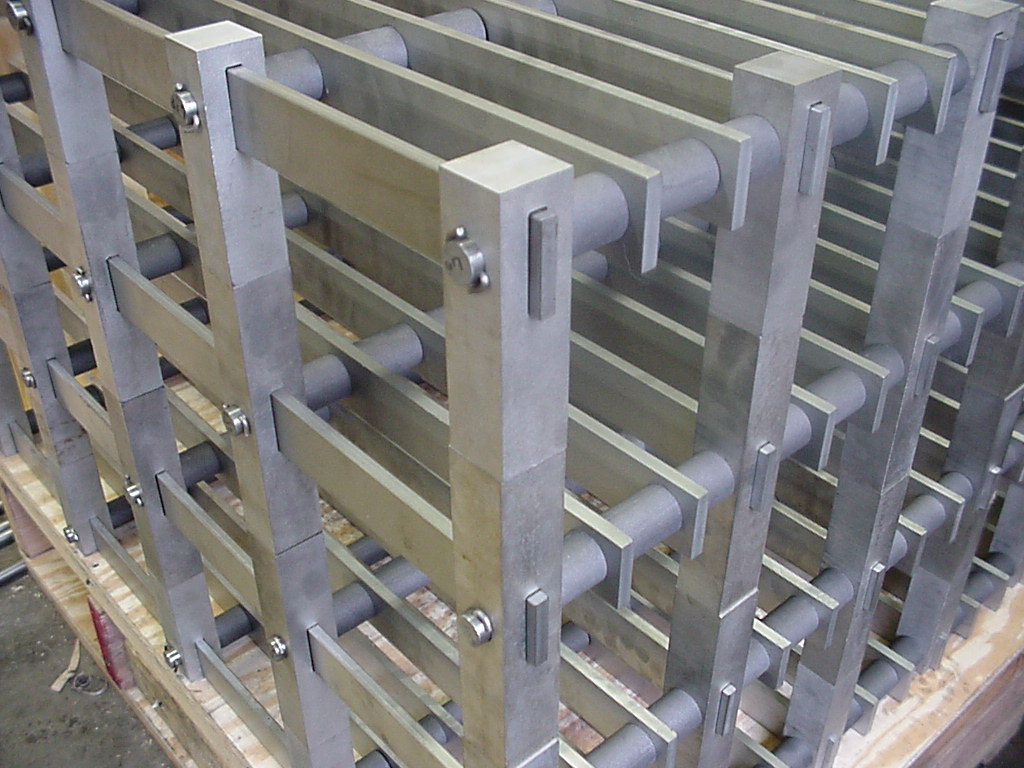

The daily production demands placed on these mission-critical furnaces dictates that they cannot be shut down for long periods of time for maintenance & repairs. For vacuum furnaces that employ parts, racks & shielding produced from molybdenum, TZM, tungsten or tantalum, the very long lead-times from producer mills dictate that vacuum furnace users either keep a very expensive inventory of refractory metal parts & shielding on site or be faced with a furnace shutdown for weeks and even months. Since a long shutdown of a vacuum furnace would do great financial & competitive harm to any vacuum furnace user, the best viable option is to look to refractory metal distributors and/or independent machine shops for urgently needed refractory metal parts & shielding.

Choosing the right refractory metal distributor & machine shop can be tricky. First, the needed products have to be in-stock or have a very short lead-time. Second, the quality & purity of the refractory metal has to be faultless and the precision-machined fabricated parts have to be flawless. Lastly & of great importance is the reliability & reputation of the company you choose to supply your urgent vacuum furnace refractory metal requirement.

Rembar is the perfect solution for urgently needed refractory metal vacuum furnace products. With one of the U.S.A.’s largest inventory of refractory metals, coupled with our in-house machine shop that can custom-machine parts quickly & to exacting specifications, Rembar is a one-stop shop for vacuum furnace refractory metal requirements. Not only does Rembar serve a long list of industrial vacuum furnace users, we also serve several well-known & industry-leading vacuum furnace producers that rely on us for machined & formed parts thanks to our commitment to supply 100% quality products and our short lead-times for fabricated parts.

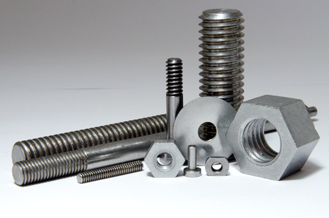

Since its founding in 1950, Rembar has built a distinguished reputation over 73 years as a reliable & trustworthy partner to the vacuum furnace industry. In addition to our extensive stock of standard thicknesses, widths & diameters of foil, sheet, plate, rod, wire, hex-head nuts, threaded rod & tubing, our machine shop has some of the shortest lead-times in the industry for machined parts.

In a hurry? Use the “Fast-Quote” form on our website, or for even faster service, call us today at 914-693-2620 & speak with one of our knowledgeable sales engineers. You’ll be glad you did.