Pure molybdenum, with its very high melting point, good strength, low coefficient of thermal expansion & excellent thermal conductivity, is a good all-around candidate for most high temperature applications.

TZM, an acronym for the molybdenum alloy “titanium-zirconium-molybdenum”, is a molybdenum alloy containing 0.5% titanium, 0.08% zirconium, 0.02% carbon and the balance molybdenum. TZM, like pure molybdenum, can be produced by powder metallurgy or arc-cast processes.

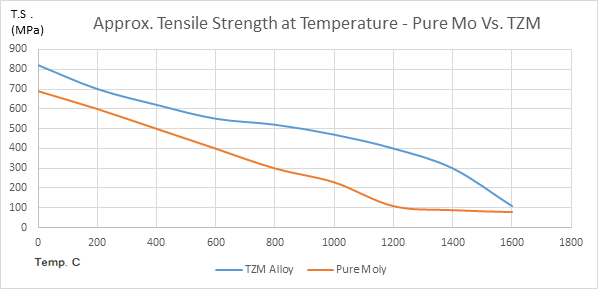

While TZM is approximately 25% more expensive than pure molybdenum, in certain applications the additional cost is offset by its increased strength at elevated temperatures. TZM has a higher recrystallization temperature than pure molybdenum, reducing the likelihood of embrittlement at higher temperatures. And in elevated temperature applications, TZM’s higher strength, hardness, creep resistance and ductility insures it will not weaken or soften.

The recommended temperatures for using TZM is between 700 and 1,400 degrees Celsius. However, like pure molybdenum, TZM begins to oxidize at 400 degrees Celsius and oxides rapidly in oxidizing atmospheres above 500 Celsius. Similar in strength to pure molybdenum at room temperatures, at operating temperatures exceeding the recrystallization temperature of pure molybdenum (900 to 1,100 degrees Celsius), TZM is much stronger. And in load-bearing applications exceeding 1300 degrees Celsius, TZM is twice as strong as pure molybdenum.

In the vacuum furnace industry, TZM is the material of choice for load-bearing hearths and horizontal posts thanks to its increased strength and higher recrystallization temperature than pure molybdenum.

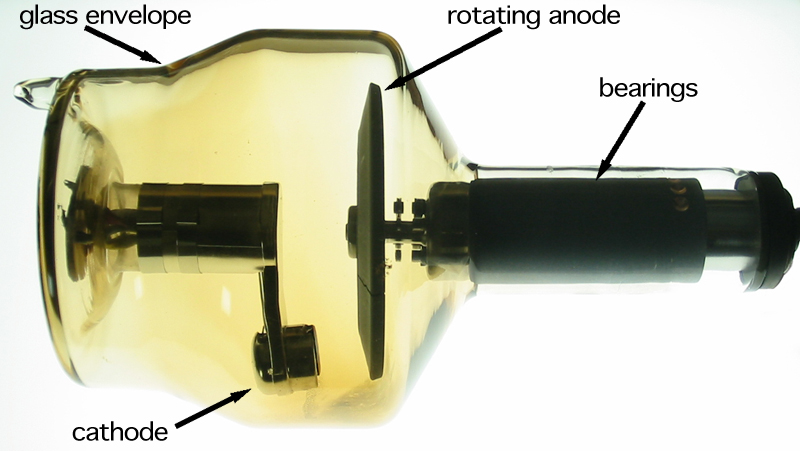

In the medical diagnostic equipment industry, TZM is used as the material of choice in rotating anodes in X-ray tubes. Despite the elevated temperature in the X-ray tube and the extremely high speed of the rotating X-ray anodes, TZM is less prone than pure molybdenum to delaminating, cracking or breaking under these extreme conditions.

In general, if your application has a demanding mechanical load at temperatures above 900 degrees Celsius, or when recrystallization and embrittlement of pure molybdenum is a concern due to repeated temperature cycling and handling, TZM is a good candidate for your application.

Our knowledgeable and experienced refractory metal sales engineers are standing by to help you select the best metal for your application. For immediate assistance, please call us at (914) 693-2620, or use our on-line “Fast Quote” form at www.Rembar.com to submit your request along with any associated drawings, documents, etc.

Remember Rembar for refractory metals. Quality & Service since 1950.